WHY INVESTING IN QUALITY TOOLING IS CRITICAL FOR PRODUCING QUALITY COMPONENTS

When you invest in high-quality stamping die components, you’re also making an investment in the quality and performance of the final product. That in turn improves your customers’ experience and your reputation as a stamper.

The die sets, guiding elements, springs, and other die tooling you select also directly impact the success of your stamping projects. Settling for lower-quality components that wear poorly or need frequent lubrication or replacement extend lead times and add to your labor requirements. Stamping with inferior components also risks higher rates of scrap or rework as tooling slips out of tolerance over time and hurts On-Time delivery requirements.

Ready Technology designs and manufactures a comprehensive selection of these critical elements for stampers serving the automotive, appliance, agricultural, heavy truck and trailer, HVAC, and other industries. In addition to supplying the equipment you need, we will use our close understanding of the metal stamping process to help you determine which products, configurations, and dimensions will meet your requirements.

Learn more about our products and what sets them apart for metal stamping applications.

PRODUCTS & SERVICES FOR METAL STAMPERS

As a leader in our industry, Ready Technology is a one-stop source of die sets and tooling for metal stampers around the world. Our comprehensive selection of stamping tooling is available in a range of materials, sizes, and designs to meet the needs of any stamping operation. Our offerings include:

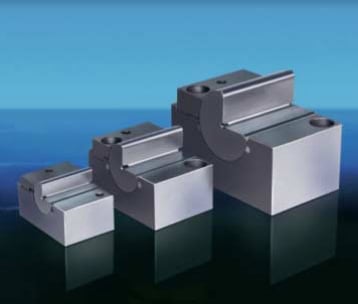

DIE SETS

Die sets are the upper and lower plates, sometimes called die shoes, that fit into a stamping press and hold springs, punches, benders, and other stamping and forming components. Die sets also include one or two matched pairs of bushings and guide pins that keep the die shoes and tooling aligned during operation. Standard plates are in stock and available in two- and four-post configurations. Additionally, two-post plates are available with back, diagonal, or center post placement.

Die sets are commonly made from A36 steel and Ready stocks standard plates in four-post or two-post configurations. Aluminum plate die sets are also available. Two-post styles have back, diagonal, or center placement. We can also custom machine die sets to meet the needs of your application with vertical and horizontal CNC milling, radial drilling, thermal burn table cutting, or press brake forming.

LEARN MORE

GUIDING ELEMENTS

Guiding elements include bushings and guide pins are assembled to the die set and keep die shoes and tooling in precise alignment during stamping. The upper die shoe typically moves down to meet the lower die shoe, and as this happens the guide pins move down into the bushings.

In most plain bearing die sets, the upper shoe travels down to meet the lower shoe, and the guide pins move down into the bushings. in ball bearing die sets, the guiding elements are reversed top and bottom. Both plain and ball bearing guide pins are available, either as straight pins, demountable pins, or double diameter press fit pins.

-

READY PLAIN AND BALL BEARING BUSHING COMPONENTS

Guiding element pairings can be designed using plain bearing pins and bushings, or with ball bearing cages to ensure smooth movement and easier die disassembly. Many diameters and lengths are available to achieve the desired fit. Plain bushings are available in steel, sintered bronze, or our SinterLube lining. All of Ready’s ball bearing pins and bushings are compatible with major ball bearing brands.

Ball bearing cages can be used with any Ready Ball Bearing Guide Pins and fit inside a sleeve or demountable bushing. Cages hold AFBMA Grade 10 in a wear-resistant, hardened aluminum alloy cage. They are arranged in a double spiral pattern for reliable and smooth rolling motion.

-

SINTERLUBE® ALLOY BUSHINGS

Ready’s SinterLube bushings are a durable, innovative alternative to standard bronze-lined or graphite-plug bushings. Machined steel bushings are lined with a special powdered bronze and high-lubricity alloy mixture, then fired in a sintering furnace. This process creates a thick layer that is bonded to the steel.

Unlike graphite plug bushings that can extrude over time, the lining in SinterLube bushings is permanent and will not flake or peel and can hold tight tolerances for thousands or millions of cycles. What’s more, they require only an initial application of high-viscosity lubricant for an entire production run. This reduces maintenance and boosts efficiency.

-

READY GUIDE PINS

Guide pins are made from hardened ball bearing-quality steel. They are available in straight, double diameter press fit, as well as demountable styles in inch or metric dimensions. All Ready guide pins can be used with plain or ball bearing bushings. Our color-coded Selective Fit™ system ensures proper running fit between pins and bushings.

DIE SPRINGS

Springs supply hold-down or forming pressure to stripper plates and form stations as well as to help lift the stock strip for the next progression. Mechanical coiled springs and nitrogen gas springs are both common choices available from Ready.

READY SUPERSPRINGS

Ready SuperSprings are traditional coiled mechanical die springs. They are manufactured in a range of diameters from vacuum degassed, valve spring quality alloy steel wire. We use trapezoidal wire, which changes to a D shape upon coiling. This new shape has a lower maximum stress level during compression, giving the spring an extended service life.

Select SuperSprings for your application based on the material being stamped, its thickness, and the nature of the part features. Compressed versus free length, hole and rod diameter, and desired preload are also important considerations.

NITROGEN GAS SPRINGS

Cost effective and space saving high pressure nitrogen gas springs and piston or stem and seals are an alternative to traditional mechanical coil springs. Instead of a wire coil, they operate based on compression and expansion of nitrogen gas. They consist of a spring housing body, a bushing, and a piston or stem and seals. When the gas is pressurized inside the housing, the spring stores potential energy, and when pressure is removed the gas expands and pushes the stem up. A small amount of lubricating oil is also sealed inside the spring housing to keep the stem moving smoothly in both directions.

Nitrogen gas springs are safe and durable, and provide immediate and fairly consistent pressure over the entire stroke length. What’s more, there is no gradual loss of force over time due to metal fatigue, as is common with mechanical springs.

CAM DRIVES

Ready Cams fit inside die sets and transfer vertical ram motion into horizontal motion to create part features. Ready cams are compact, self-lubricating, and come in a range of standard point diameters and stroke lengths for different tonnages. Cams are available in three types: