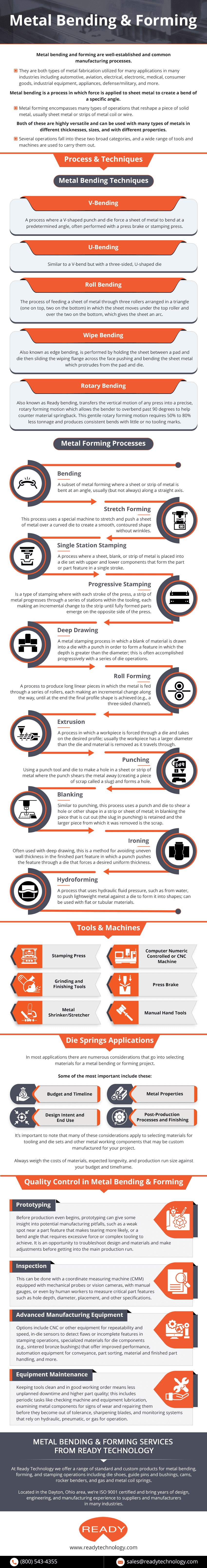

Metal bending and forming are well established and common manufacturing processes. They are both types of metal fabrication utilized for many applications in many industries including automotive, aviation, electrical, electronic, medical, consumer goods, industrial equipment, appliances, defense/military, and more.

Metal bending is a process in which force is applied to sheet metal to create a bend of a specific angle. Metal forming encompasses many types of operations that reshape a piece of solid metal, usually sheet metal or strips of metal coil or wire.

Both of these are highly versatile and can be used with many types of metals in different thicknesses, sizes, and with different properties. Several operations fall into these two broad categories, and a wide range of tools and machines are used to carry them out.

Here we will look at some common operations, tools and machinery, material considerations, and quality control tips for metal bending and forming processes. Keep reading to learn more!

Process & Techniques

There are many methods of bending and forming metal to choose from, depending on the application and part specifications. Some examples include:

Metal bending techniques

- V-bending – a process where a V-shaped punch and die force a sheet of metal to bend at a predetermined angle, often performed with a press brake or stamping press

- U-bending – similar to a V-bend but with a three-sided, U-shaped die

- Roll bending – the process of feeding a sheet of metal through three rollers arranged in a triangle (one on top, two on the bottom) in which the sheet moves under the top roller and over the two on the bottom, which gives the sheet an arc

- Wipe bending – also known as edge bending, is performed by holding the sheet between a pad and die then sliding the wiping flange across the face pushing and bending the sheet metal which protrudes from the pad and die

- Rotary bending – also known as Ready bending, transfers the vertical motion of any press into a precise, rotary forming motion which allows the bender to overbend past 90 degrees to help counter material springback. This gentile rotary forming motion requires 50% to 80% less tonnage and produces consistent bends with little or no tooling marks

Metal forming processes

- Bending – a subset of metal forming where a sheet or strip of metal is bent at an angle, usually (but not always) along a straight axis

- Stretch forming – this process uses a special machine to stretch and push a sheet of metal over a curved die to create a smooth, contoured shape without wrinkles

- Single station stamping – a process where a sheet, blank, or strip of metal is placed into a die set with upper and lower components that form the part or part feature in a single stroke

- Progressive stamping – is a type of stamping where with each stroke of the press, a strip of metal progresses through a series of stations within the tooling, each making an incremental change to the strip until fully formed parts emerge on the opposite side of the press

- Deep drawing – a metal stamping process in which a blank of material is drawn into a die with a punch in order to form a feature in which the depth is greater than the diameter; this is often accomplished progressively with a series of die operations

- Roll forming – a process to produce long linear pieces in which the metal is fed through a series of rollers, each making an incremental change along the way, until at the end the final profile shape is achieved (e.g., a three-sided channel)

- Extrusion – a process in which a workpiece is forced through a die and takes on the desired profile; usually the workpiece has a larger diameter than the die and material is removed as it travels through

- Punching – using a punch tool and die to make a hole in a sheet or strip of metal where the punch shears the metal away (creating a piece of scrap called a slug) and forms a hole

- Blanking – similar to punching, this process uses a punch and die to shear a hole or other shape in a strip or sheet of metal; in blanking the piece that is cut out (the slug in punching) is retained and the larger piece from which it was removed is the scrap

- Ironing – often used with deep drawing, this is a method for avoiding uneven wall thickness in the finished part feature in which a punch pushes the feature through a die that forces a desired uniform thickness

- Hydroforming – a process that uses hydraulic fluid pressure, such as from water, to push lightweight metal against a die to form it into shapes; can be used with flat or tubular materials

Tools and Machines

Metal bending and forming are done with a variety of manual, automated, and semi-automated tools and machines. Some examples include:

- Stamping press – a machine that is fitted with a die set and tooling to perform standard or progressive stamping operations; uses different tonnages to drive a ram with appropriate force to form parts from many types of metals

- Computer numeric controlled or CNC machine – semi- or fully-automated piece of equipment that is programmed to perform a certain operation and repeats the cycle automatically when a new blank or workpiece is loaded; common CNC operations include: drilling, lathe/turning, milling, panel bending, turret press punching, laser cutting

- Grinding and finishing tools – includes deburring, grinding, polishing, often performed with handheld tools though it is also possible to use a collaborative or industrial robot to perform finishing tasks for larger scale production quickly and with great precision

- Press brake – a machine used for bending sheet or plate metal along a straight axis by clamping it in place between a tool and die; can be mechanical, CNC, pneumatic, or servo-electrical machines depending on the material type and tonnage required for the application

- Metal shrinker/stretcher – smoothes out curves in metal, removing wrinkles and other imperfections

- Manual hand tools – mallets, hammers, forming heads, deburring tools, seamers, snips and others for finishing and other detail work

Material Selection and Design Considerations

In most applications there are numerous considerations that go into selecting materials for a metal bending or forming project. Some of the most important include these:

- Budget and timeline – consider if you or your vendor can obtain the material at a cost-effective price, in the timeframe required to satisfy demand or bring a new product to market

- Metal properties – which properties are critical always depends on the application and end use in question, and on how each metal “behaves” during forming or bending; some materials may be better suited to different processes, but critical properties may include:

- Conductivity, thickness, weight, corrosion resistance, surface finish, tensile and yield strength, ductility, percentage of elongation, surface hardness, bendability and springback

- Design intent and end use – especially where safety concerns are present you may have fewer options for materials, such as food-grade, medical equipment, or automotive/transportation industry applications; however, in other cases it may be possible to find a suitable substitute material or manufacturing process to save costs, such as using pre-plated materials or selectively plating a more expensive metal only where it’s needed on a part

- Post-production processes and finishing – keep in mind how much deburring, grinding, painting, polishing, cleaning will be required to complete each part and what time and monetary costs that adds; it may be worth asking if there any design or manufacturing process tweaks that may reduce these, such as making a laser cut instead of shearing if it suits the application

It’s important to note that many of these considerations apply to selecting materials for tooling and die sets and other metal working components that may be custom manufactured for your project. Always weigh the costs of materials, expected longevity, and production run size against your budget and timeframe.

Quality Control in Metal Bending and Forming

In today’s manufacturing environment, tight tolerances and short turnaround are common. That means not only do parts have to be made efficiently, but scrap must be minimal whenever possible. For these reasons, quality control (QC) should remain top of mind. All of these are QC best practices:

- Prototyping – before production even begins, prototyping can give some insight into potential manufacturing pitfalls, such as a weak spot near a part feature that makes tearing more likely, or a bend angle that requires excessive force or complex tooling to achieve. It is an opportunity to troubleshoot design and materials and make adjustments before getting into the main production run.

- Inspection – this can be done with a coordinate measuring machine (CMM) equipped with mechanical probes or vision cameras, with manual gauges, or even by human workers to measure critical part features such as hole depth, diameter, placement, and other specifications

- Advanced manufacturing equipment – options include CNC or other equipment for repeatability and speed, in-die sensors to detect flaws or incomplete features in stamping operations, specialized materials for die components (e.g., sintered bronze bushings) that offer improved performance, automation equipment for conveyance, part sorting, material and finished part handling, and more

- Equipment maintenance – Keeping tools clean and in good working order means less unplanned downtime and higher part quality; this includes periodic tasks like checking machine and equipment lubrication, examining metal components for signs of wear and repairing them before they become out of tolerance, sharpening blades, and monitoring systems that rely on hydraulic, pneumatic, or gas for operation

Metal Bending & Forming Services from Ready Technology

At Ready Technology we offer a range of standard and custom products for metal bending, forming, and stamping operations including die shoes, guide pins and bushings, cams, rocker benders, and gas and metal coil springs.

Located in the Dayton, Ohio area, we’re ISO 9001 certified and bring years of design, engineering, and manufacturing experience to suppliers and manufacturers in many industries. Please contact us or request a quote for your metal forming needs!